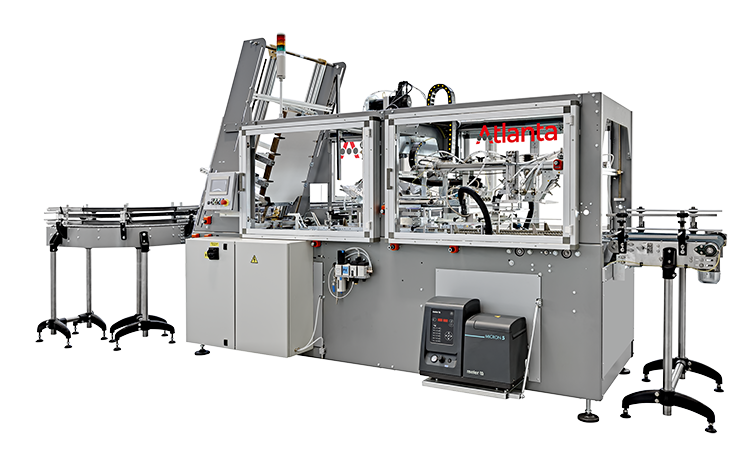

Raffaello

Raffaello is a compact automatic case-packing machine. Particularly suited to low to medium-speed production lines where space is tight, with a speed of up to 15 packs per minute. Modular in design and available in a range of configurations to suit specific applications.

- Small footprint – less than 4 meters in length

- Multi-layer option with precision pick and place up to 4 layers

- Low cost and easy maintenance

- Ergonomic design for safe ease of use

- Operator-friendly size change

- Simple intuitive operator HMI touchscreen

- Capability to load trays, full cases and/or SRP’s

General Characteristics

- Maximum attention to safety. Each moving part is protected to ensure the safety of line operators.

- Sliding safety guards allow the operator to have full view of the machine, the wide opening ensures easy access during maintenance and cleaning.

- Machine designed to operate over three shifts, with low energy consumption and silently.

- Touch screen panel with simple and intuitive interface: this allows the operator to quickly set all parameters and has a broad range of pre-sets.

- Pick&Place module available with different versions, including magnetic, suction cups and vanes.

- Quick format changeover pre-set that can be activated from the standard touch screen control panel.

- Combined blank and product detection with sensors and photocells.

Technical specifications

- Production speed up to 15 cartons/trays per minute

- Blank thickness 2 to 5 mm

- Upper flap closure internal

- Installed power 13 kW

- Voltage 400V – 3-Phase/50Hz + N + G

- Electrical protection IP54

- Compressed air consumption 400 NI at 6 bar

- Operating temperature min +5°C – max +40°C

- Relative humidity max 70%

- Total weight 2,500 kg

- Product presence check feelers + photocells

- Machine colour RAL 7037 (gray)

Options

- Partial automatic format changeover

- Additional channels

- Inserter device unit

- Separating sheet inserter for multi-layer packages

- Adjustable feeding guides with handwheels

- Manual or automatic centralized lubrication

- Motorized crossover infeed conveyor

- Photocells for product presence check after separation phase

- External upper flap closure

- Customized RAL colour

- Electrical panel air conditioning

- Interface with host computer for data transfer

- Teleassistance

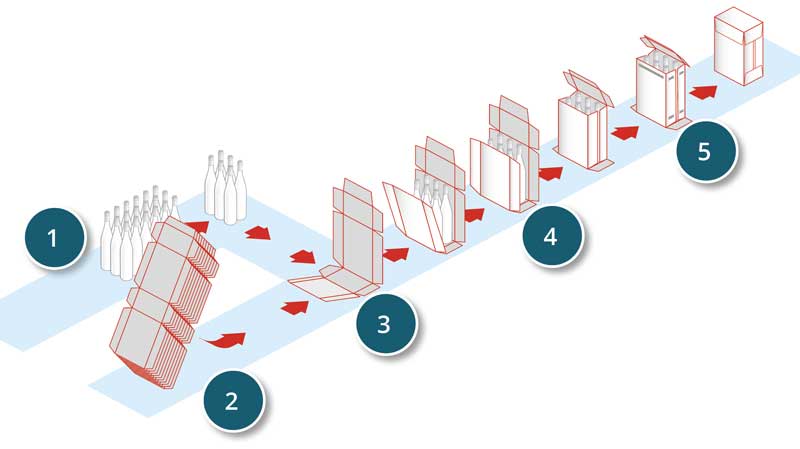

Operation

- Loose products can arrive in-line (also through a crossover infeed conveyor) or at 90°.

- The blank is taken from the magazine by a suction cup system.

- The first fold prepares the blank to receive the group of products.

- The box is formed around the product with consecutive folds, while passing along the production line.

- Glued points are applied and the flap can be internal (standard) or external (optional).