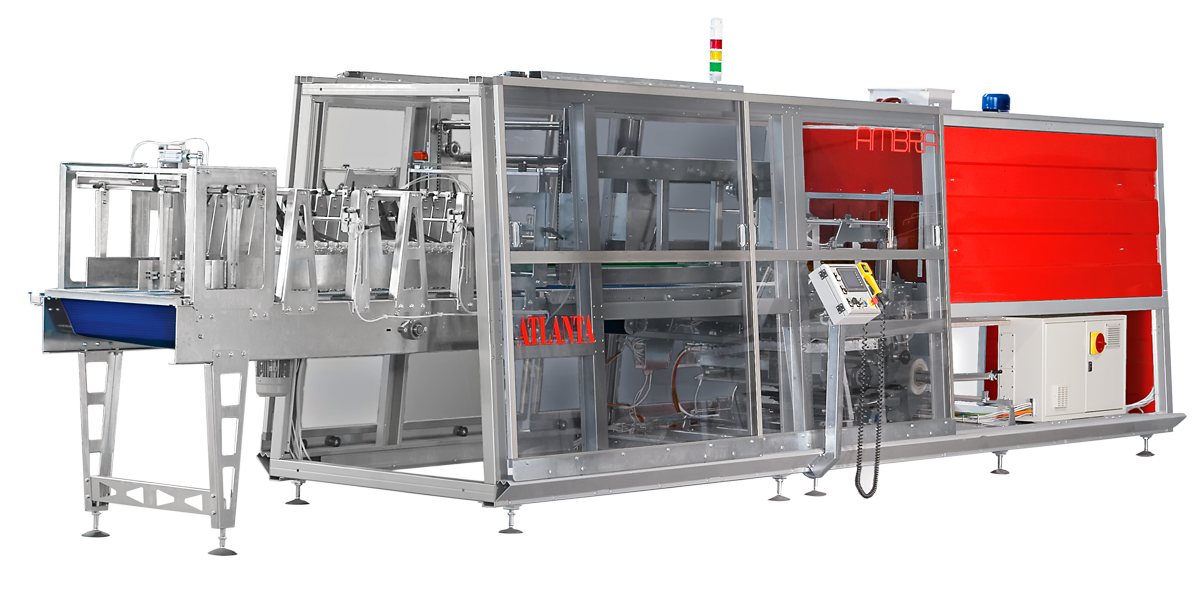

Ambra

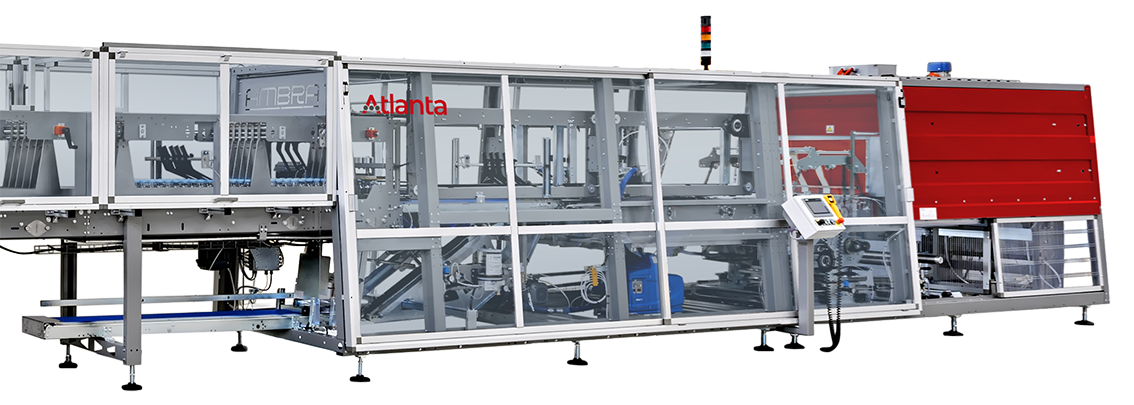

Ambra is a reliable, quick and easy-to-use entry-level automatic packaging machine with a film feeder. Compact in size and a simple format changeover make it the ideal solution for various applications in the beverage, food, detergent and personal care sectors.

- Up to 1,800 packs/hour

- Minimal maintenance and costs

- Designed for safe and easy inspection and emptying

- Mechanical and optic sensors

- Tailored feeding options

- Highly efficient shrink tunnel

- Touch screen control panel

General characteristics

- Frame and mechanical parts without welding to ensure utmost efficiency and consistency of performance over time.

- Each moving part is protected to ensure the safety of line operators.

- Sliding safety guards allow the operator to have full view of the machine, the wide opening ensures easy access during maintenance and cleaning.

- Machine designed to operate over three shifts, with low energy consumption and silently.

- High efficiency heat-shrink tunnel even with several lanes in operation.

- Touch screen panel with simple and intuitive interface: this allows the operator to quickly set all parameters.

- Quick format changeover by means of the standard touch screen control panel; it normally does not require replacing parts.

- Optional automatic format changeover.

- High precision centring of the printed film also on several lanes.

- Combined product presence check in the channels, both with feelers and with photocells.

- Available in partial or full stainless steel versions.

Technical specifications

- Cutting blade length: 700 mm

- Installed power: 45 kW – 50 kW

- Voltage: 400V – 3 Phase / 50 Hz + N + G

- Auxiliary voltage: 24V DC/AC

- Electrical protection: IP54

- Compressed air consumption: 100 NI/cycle at 6 bar

- Operating temperature: min +5°C – max +40°C

- Relative humidity: max 70%

- Total weight: 3,300 kg – 4,000 kg

- Product presence check: feelers + photocells

- Machine colour: RAL 7037 (gray), RAL 3020 (red)

Options

An extensive range of optionals to make this shrink-wrap machine perfect for your production line:

- Automatic format changeover

- Printed film: centring

- Second reel holder

- Double or triple lane for small formats

- Adjustable feeding guides with handwheels

- Manual or automatic centralized lubrication

- Motorized crossover infeed conveyor

- Photocells for product presence check after separation phase

- Pneumatic motor to empty oven in case of power shut off

- Electrical panel air conditioning

- Partial stainless steel version

- Customized RAL colour

- Teleassistance

- 4.0 Industry

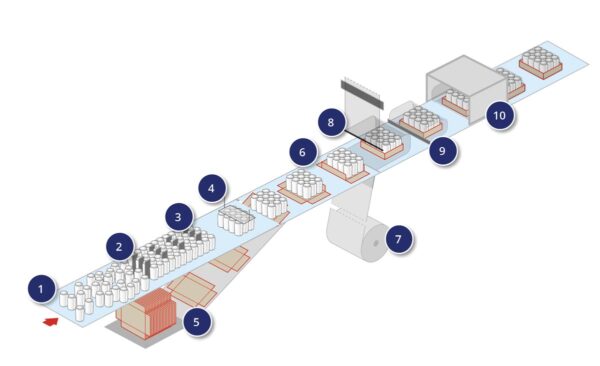

Operation

- Loose product feeding, arriving in-line, on a crossover infeed conveyor, or at 90°

- Pneumatic anti-jamming unit with oscillating separating bars for proper channelling of the product.

- Maximum accumulation sensor to check the incoming belt. Minimum accumulation sensor for each channel.

- Alternated separation without mechanical gears.

- High capacity blank magazine for pads and trays, located on the bottom, with easy access to be quickly refilled.

- Tray closed with glue points.

- Film feeding by means of a pair of rollers powered by a brushless motor.

- Precision pneumatic film cutting.

- Neutral or printed film wrapping by means of a bar that can be adjusted according to the height of the product.

- High energy output heat-shrinking tunnel.